Pallet handling robot application

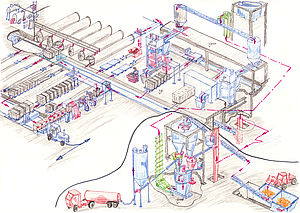

The engineers of WKB Systems worked out a smart robot application solution for the packing area to arrange all the workflows more effective and well-organised. Furthermore, the logistic costs by using interlaced pallets can be reduced.

The robot used is usually an articulated robot with 6 axes that ensures a very high level of flexibility. The robot is fitted with a special pneumatic gripper. The main task of the robot is to take a pallet from the storage area and place it on a conveyor of the packing line. Before starting the process, the robot recognises with special sensors, if a pallet is interlaced or not. Then the gripper takes every single pallet, turns it at 180°, if needed, and feeds the conveyor with it. Furthermore, the robot uses special fingers to place the pallet right in the middle of the conveyor or any other point of placement needed.

Furthermore, the automatic pallet handling by WKB Systems is completed with a pallet storage and conveying systems up to the packing line.

The application can be also realised with a control system, safety technology and CE from a single source, with any individual design being possible.