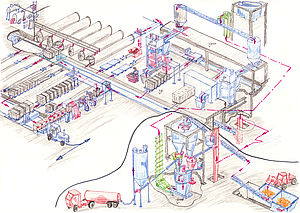

Hardening trolley circulation

A crucial part of a sand-lime brick plant, which impacts on the product quality, is the circulation of the hardening wagon. Internal transport and careful handling are key to producing a flawless sand-lime brick.

As regards the hardening wagon logistics we can specifically offer you:

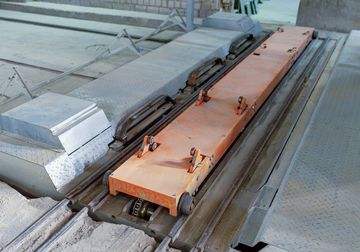

- Traversers

- Hardening wagons

- Transport systems

- Incremental drive

- Steel rope systems

- Electric control system with product tracking

- Scraper / hardening wagon brushes for the cleaning systemsn

In our sand-lime brick production plants the empty hardening wagons of the press are transported using a traverser for empty wagons (accommodating one to two wagons). The pressed sand-lime brick blanks are automatically removed from the press with the gripper and stacked on the empty hardening wagon. A traverser, which can carry up to six hardening wagons, then transports the full wagons from the press tracks for autoclaving. After autoclaving, another traverser collects the hardening wagon with the hardened bricks from the autoclave and transports them to the packaging area.

When equipping the traverser, you can have a choice between an incremental drive or a "locomotive" drive. Talk to our team of experts and let us advise you on the best option for your plant.