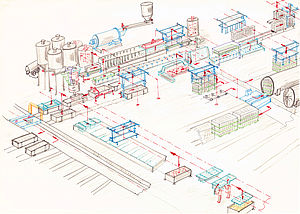

Casting mould transfer and fermentation process

The mass is discharged into the oiled casting mould from the mixing plant.The great importance is attached to maximum water-tightness and closing force in the design and construction of the mould.

The following steps of the casting mould transfer are implemented using a fully automated, state-of-the-art technology: The filled mould is moved automatically into one of the fermentation chambers with friction wheel drives and a traverser. Fermentation chamber is a closed and heated area, in which the mould remains for a defined period of between 2.5 - 4 hours (depending on the recipe) so that the fermentation process can be completed. Here is a small excerpt of the chemical reactions that occur within the mix during this period:

- Volume expansion due to swelling

- Pore formation in the cake due to foaming of the aluminium

- Hardening to a cake suitable for cutting.

As far as preset characteristics of the so-called green cake are exactly reached the mould is forwarded to the demoulding area. The mould transport is implemented with a technically high-quality and completely automated mechanism.