Cleaning system for hardening wagon

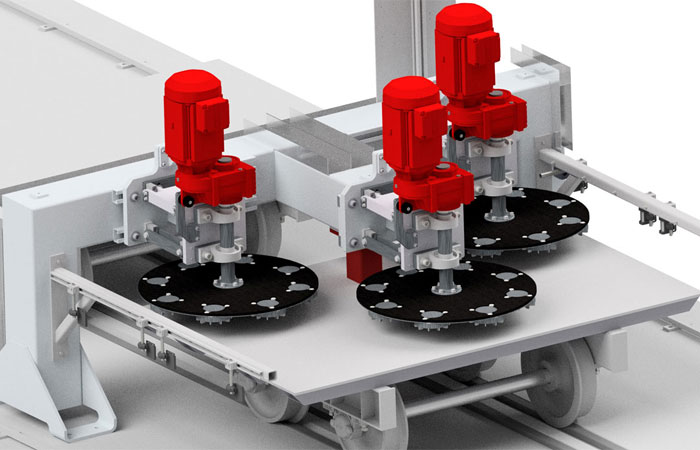

The use of our hardening wagon cleaning device prevents the brick blanks and the hardened bricks from being scratched or damaged. For cleaning the hardening wagons of any caking, we have developed a special cleaning machine:

The hardening wagon is driven using a wagon advance underneath the system to be cleaned. After the hardening wagon is fixed, the two rotary plates driven in parallel by a frequency converter are rotated and lowered pneumatically and electrically under the control of a photoelectric sensor. In the WKB Systems cleaning control, the speed can be regulated using a potentiometer. The rotary plates are fitted with cleaning blades (roughing or finishing blades).

Another photoelectric sensor controls whether a third rotary plate is lowered and activated. Here, too, the speed can be set variably. As soon as the hardening wagon leaves its cleaning position, the corresponding rotary plate is lifted.

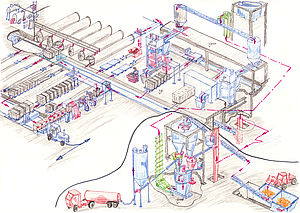

The hardening wagon is then transported back into the hardening wagon circulation.