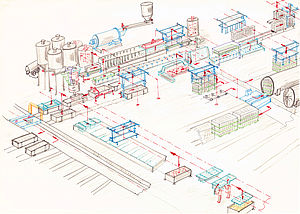

Cutting lines

WKB-CL 1 and WKB-CL 2 for precise cutting of the cake; WKB-CL 4 for modernisation your AAC plant

After demoulding, the cutting process is initiated. The WKB Systems cutting lines reflect the symbiosis between state-of-the-art technology and constant innovation. When developing our systems, we attach great value to user-friendliness.

WKB Systems has developed a number of system concepts for you, of which we would like to explain three of these in more detail here. All three versions are of course individually adaptable to your needs.

The basic version, WKB-CL 1, and the pro version, WKB-CL 2: Both systems are designed to increase the efficiency of production, to always provide precision cutting results, and to always produce precision matches of the cakes both with regard to size and shape.

Components that are common to both cutting lines include:

- Precutter: Here a bevel is cut off at right angles from the horizontally lying cake.

- Tilting device 1: The cake is tilted by 90°, so that the cut surface is perpendicular to the cutting plate.

- Transport system: The cutting plate is placed on a car, which is pulled through the cutting line using a steel rope.

- Vertical cutter: Here the sides of the upright standing cake are cut to size using tensioned wires and blades (brick length) and, if necessary, tongues and grooves are also inserted.

- Horizontal cutter: Here, the brick thickness and width are cut. The pneumatically clamped and staggered steel wires have a continuously adjustable inlet and outlet angle of 0 - 60°. In this way any breaking off of material can be prevented when the cutting wires are removed.

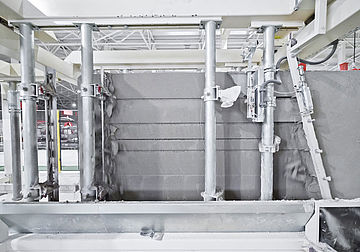

- Cross cutter: Tensioned wires, arranged depending on the format, move in an oscillating and counter directional way, and cut the brick height while descending through the cake. A pocket milling device can also be used here. We will be happy to advise you in this regard. A suction hood removes the top slice by applying a vacuum. This then falls, just as the header sides of the cake do, into the cutting pit before it is then re-fed back into the production process via a conveyor belt.

- Tilting device 2: Being cut the cake is then tilted onto a pre-positioned autoclave pallet or an autoclaving grate. After the cake slides off the cutting plate, the bottom slice, previously held in place by vacuum, is also disposed of in the cutting pit.

- Cutting plate return: The now released cutting plate is transported with a portal unit above the cutting line from the tilting device 2 back to the tilting device 1.

Due to its high performance and precision, the basic WKB-CL 1 version is extremely popular amongst our customers.

In an advanced version, WKB-CL 2, we have added a second transport car. This moves in the cutting pit between the cross cutter and tilting device 2. A lifting device under the cross cutter allows these two transport cars to be exchanged. This WKB Systems technology enables an even faster throughput time of the cutting line and thus provides higher production efficiency.

The compact cutting line WKB-CL 4 for modernisation of your plant

In addition to the above-mentioned cutting lines, the WKB-CL 4 system was specially developed for the modernisation purposes of autoclaved aerated concrete plants. This development was designed to allow our customers to be always supplied with the most up-to-date equipment. The system is fully customisable. This features cutting-edge technology and occupies a very small footprint. In this way it can be integrated into almost any AAC plant. In contrast to the CL1 and CL 2 versions, the compact cutting line CL 4 has only one tilting device. By cutting single modules go "through" the cake, the cake is processed in an upright position.

The vertical and horizontal cutting devices are designed to be mobile and process the aerated concrete cake at the same time. The mode of operation of the transverse cutter complies with the tried-and-tested mode of our other cutting lines.

Do you want to stay up-to-date with the latest technology and replace your old cutting line? The WKB-CL 4 is the answer to your need for modernisation in aerated concrete production.

Like all of our systems, the WKB Systems cutting lines are at the cutting edge of technology. We combine our ever-advancing innovation with the highest efficiency and user friendliness. We would be very happy to meet any of your individual requirements (for example, customisation of brick formats). Please do not hesitate to contact us so that we can help you develop your own customised system.