Autoclaving

The blanks are advanced onto hardening wagons into the autoclaves. Autoclaves are pressurised steam chambers in which the sand-lime bricks acquire their final strength. The sand-lime bricks achieve their final strength at approximately 200 °C and a steam pressure of 16 bar. The hardening time depends on the density and size of the sand-lime bricks and usually takes about eight hours.

This is exactly when the structural change takes place. The individual steps of this process are individually set in advance in our autoclave control. The entire hardening process runs automatically: The structures of lime, sand and water formed during the manufacturing process are responsible for conveying the solid structure of the sand-lime brick. During the hardening process, silicic acid is released from the surface of the quartz sand grains by the hot steam atmosphere. The silicic acid binds to the binder to form hydrated lime crystalline binder phases - the CSH phases - which grow on the grains of sand and firmly interlock them.

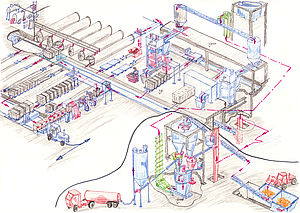

The autoclave section consists of the following individual systems:

- Feed water treatment system

- Steam generating system

- Steam distribution system (manual / automatic)

- Autoclave with drainage

- Condensate recovery system

When planning your autoclave section, we attach great importance to the efficiency and effectiveness of your plant. A central aspect is waste heat recovery.

The process step that consumes the most steam is the hardening of the material in the autoclave. Several autoclaves are very often operated in a staggered manner. This increases the amount of steam that is required.

In our plants, waste heat recovery is employed for condensate re-use as well as the use of steam generated for autoclaving. When an autoclave is shut down, steam is then diverted via the steam distribution unit to heat up another autoclave.

The condensate can then be used in the mixer. Other options are to recover the heat from the condensate through a heat exchanger and to use it then to prewarm the feed water or to heat the building.