Fully automated loading and unloading of a cooling line

with flexibly adjustable transport units and a data acquisition system

Our client, one of the world's leading forging operations in Germany that specialises in crankshaft production, was looking for a system that is capable of transporting forged crankshafts (1 - 4 cylinders) gently and universally from the remodelling process through to the final inspection. As part of the development of a completely new and fully automated forging line, the customer placed increased emphasis on production efficiency, quality control and the operation readiness of the system. At the same time, the system was to be designed as flexibly as possible, so that the demands of the future could be met.

Our solution: Automation of a cooling line

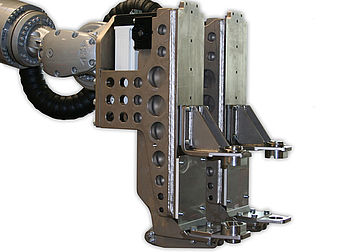

Our WKB Systems experts developed a flexible transport system, which also features product-specific adjustable transport units (TU). The loading and unloading of the TUs was fully automated through the use of robotic technology. The TUs were designed to accommodate up to eight forged items simultaneously. This not only significantly shortens the cooling line, but also significantly increases production and energy efficiency. It was particularly advantageous that the shape of the product was of little consequence, whereby the TU change times could be significantly minimised.

Considerably higher system flexibility is achieved thanks to the use of multiple drive chains in a power & free system with the integration of buffer lines.

In addition, we also equipped the transport system with a TU tracking and product data management. Using this equipment, the production data over the entire conveyor line is collected, stored and forwarded to a higher-level data management system. This allows traceability for each and every product and production step. It just wouldn't be possible to have any more quality control.

Are you also looking for solutions that will help to achieve automation? Do you also want to increase the efficiency of your plant? Call our specialists for process automation directly and talk to us about your ideas. Together we will find the ideal solution for you and your business.