Sand lime bricks production

Sand lime bricks factory from WKB Systems: The most innovative technology, individual design and end products of the highest quality

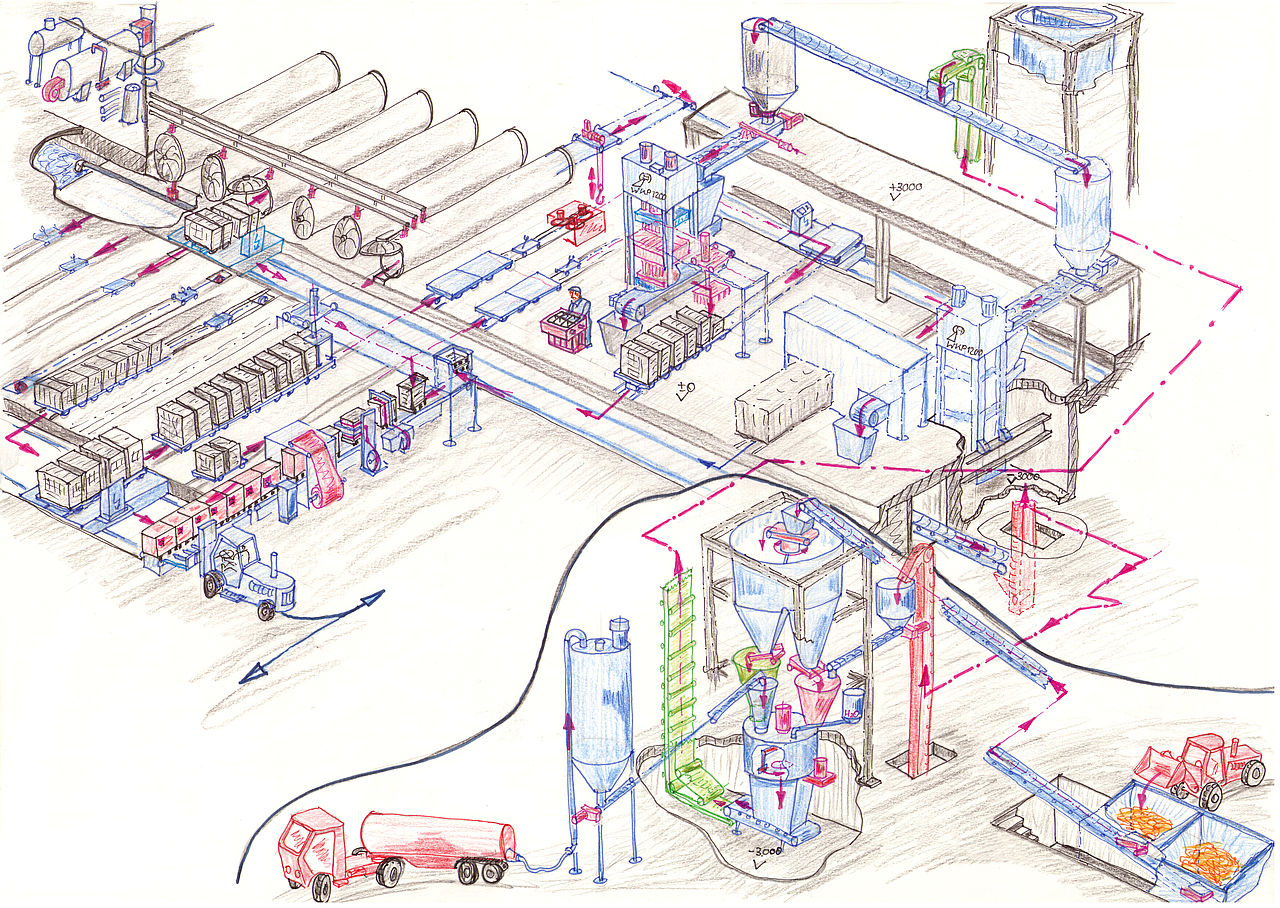

For sand lime bricks production we develop and build highly innovative machines and systems as well as complete production plants. In this capacity we cover all production areas of the modern manufacturing process. We value systems that are perfectly tuned to one another. Only then will products of the highest quality be made. Get to know the WKB Systems plants and systems we offer for manufacturing the highest quality sand lime bricks.

1Raw material processing

The different sand lime brick raw materials are stored separately in the sand-lime silos. They are forwarded to the premixing system with a conveyor and dosing system. Here, water is fed to the still dry raw material mix. read more

2Reactor

The ready mix is transported to the reactors with conveyor belts and bucket elevators. In the reaction vessel, the anhydrous lime is converted to calcium hydroxide as a result of a chemical reaction involving water. read more

3Double-shaft mixer

The double-shaft mixer, also called the remixer, is located between the reactor and the press. It is equipped with an automatic water-dosing unit which ensures that an optimum pressing humidity of the mixture is achieved shortly before pressing.

read more

4Sand lime bricks press

At the heart of our sand lime bricks plant are WKP presses. Their construction and electric control system are state-of-the-art. The technical design enables the production of solid and perforated bricks, coloured sand lime bricks and bricks with undergrips. The WKP-presses guarantee precise brick dimensions and an even compressive strength. read more

5Autoclaving

The green bricks are forwarded onto hardening carriage into the autoclaves. The sand lime bricks achieve their final strength at approximately 200 °C and a steam pressure of 16 bar. The hardening time depends on the density and size of the sand lime bricks and usually takes about eight hours. read more

6Hardening carriage circulation

In our sand lime bricks plants the empty hardening carriages are transported with a traverser for empty carriages to the press. Then a traverser for green bricks transports the full carriages from the press rails to the autoclaves. After autoclaving process another traverser collects the hardening carriages with the hardened bricks from the autoclaves and transports them to the packaging area. The cleaned hardening carriages are then returned to the press with the traverser for empty carriages. read more

7Cleaning system for hardening carriage

The hardening carriage cleaning device ensures that the surface of the carriage remains free of caking and that the bricks are not scratched or damaged.

read more

8Packaging

The most popular mode of packaging is the combination of vertical and horizontal strapping and foiling of the brick packages. read more

Our sand lime bricks plants consist of these production areas. In addition, we also offer the design and construction of special machines such as colour mixing plants.

Any questions? Our team of experts will be happy to advise you.