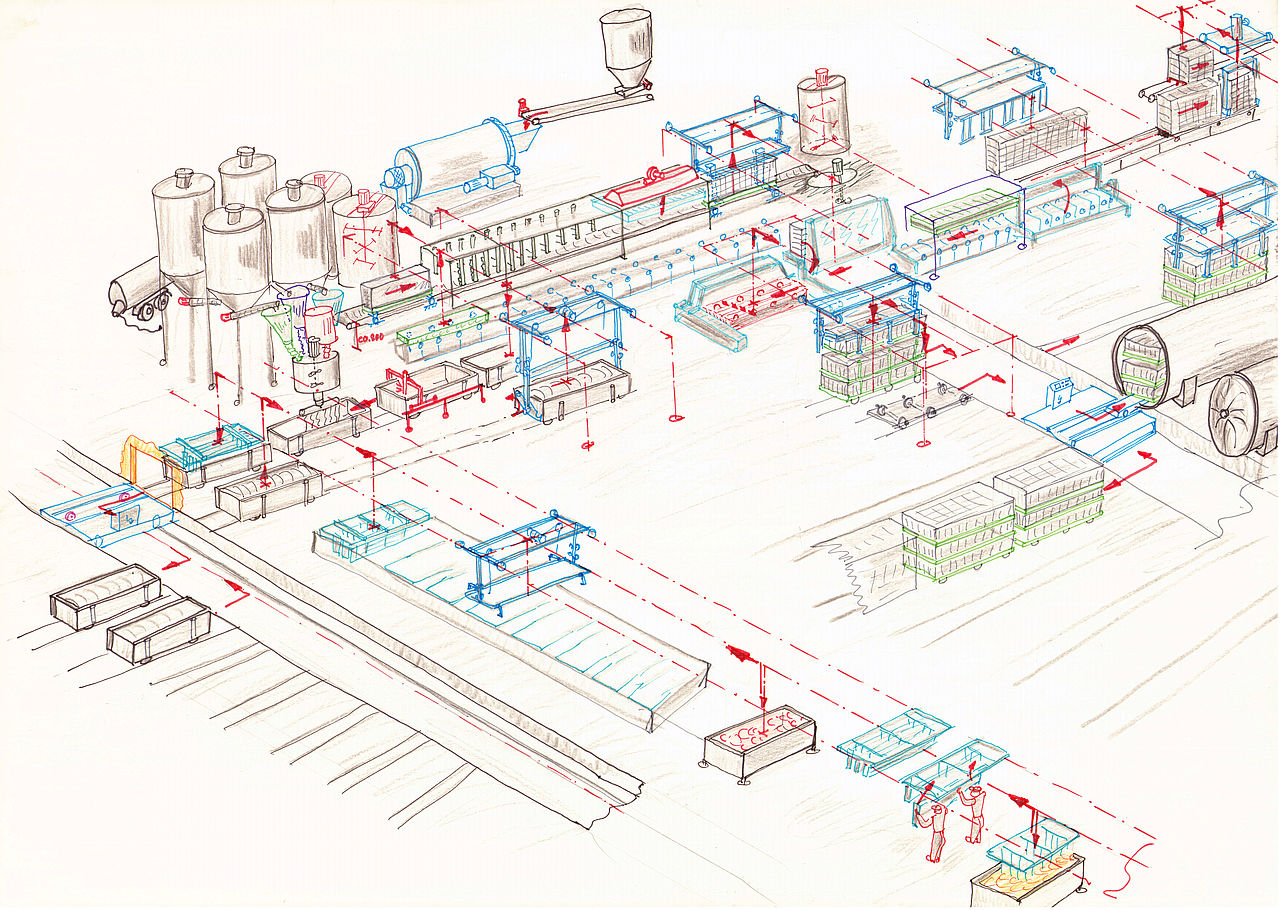

Autoclaved aerated concrete (AAC) production plants

Innovative and tailor-made equipment and AAC plants made by WKB Systems

WKB Systems provides a comprehensive range of products for manufacturing of autoclaved aerated concrete (AAC) - and all of this individually tailored to your needs.

We offer you everything you need for the production of AAC from a single source: From the development to the construction of our highly innovative machines, systems and complete AAC plants. We accompany you from the original idea, through the design and planning process, ultimately to its practical implementation and beyond. At the end you will have an AAC production plant exactly tailored to your needs or equipment, which exactly meets your expectations.

1Raw materials processing

The raw materials (quicklime, cement and anhydrite or gypsum) are stored in the storage silos and fed to the mixer in a controlled process. The alupaste is mixed with water in the aluminium plant. read more

2Ball mill for wet grinding

The quartz sand is prepared with a certain quantity of water in the ball mill for wet grinding to form a sand sludge. read more

3Mixing plant

The precisely weighed raw materials are fed in a specified order to the mixer container. Here a homogeneous mass is produced exactly according to the recipe specifications that are set and processed using a control system. read more

4Insertion of reinforcement

The anti-corrosion layer is applied onto the reinforcement mats or frames in a dipping bath. They are then fixed and adjusted in the mould with special brackets before the aerated concrete mixture is poured over. read more

5Fermentation

The aerated concrete mixture is poured from the mixer into an oiled mould. After that, the filled moulds are transferred to the heated fermentation chambers, where they remain for approximately 2.5-4 hours depending on the recipe. This is precisely when the fermentation process takes place. read more

6Demoulding and oiling

As soon as the pre-determined characteristics of the green cake are achieved, the mould is forwarded to the demoulding area. Here the cake is gently separated from the mould. The empty mould can be oiled either manually or in a completely automated way before it is prepared for re-filling under the mixer. read more

7Cutting line

Before cutting, the AAC cake is tilted by 90°. Standing upright, the cake goes through the individual stations of the cutting line (vertical cutter, horizontal cutter and cross cutter). WKB Systems offers number of cutting line variants to suit your production capacity levels. read more

8Green cake separation

In order to prevent the sticking of AAC blocks during the autoclaving, they are carefully separated with a green cake separation machine (GSM). The autoclave grate with the separated AAC cake is then placed on an autoclave carriage. read more

9Autoclave carriage circulation

The ready stacked autoclave carriages are gradually driven automatically into the autoclave. After the autoclaving process finished, the carriages are put on the unloading track to be destacked with a portal system. The empty carriages are then transferred by the portal system to the loading track and re-stacked. read more

10Autoclaving

The autoclaving is carried out in long pressure vessels (autoclaves). The autoclaving process is carried out according to precisely defined procedures. The usual duration is between 10 and 12 hours. During autoclaving, the aerated concrete acquires its final quality properties. read more

11Packaging

The hardened and transportable AAC blocks are packed in the packing line either manually or in a completely automated way. For this purpose, WKB Systems offers a number of system concepts. read more

These production areas are presented as standard in any of our AAC plants. In addition, WKB Systems also offers the development and construction of many specialised solutions. Take a closer look at our machines used for the production of U-shells or perforated blocks. We also develop state-of-the-art installations for the production of reinforced AAC elements to expand your portfolio and strengthen your market position.

Which system is best for you? Ask our team of experts for advice.