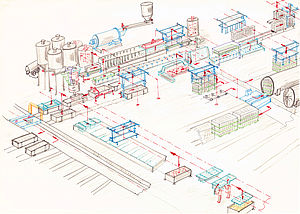

U-shells gluing station with perforation drilling machine

We offer the production of U-shells and perforated blocks as an additional option. It is possible to integrate a single machine into existing AAC plant or as a stand alone production line.

Here you have the choice between two manufacturing processes of U-shells:

- Our milling procedure involves use of a milling device to carve a groove into the aerated concrete brick so that a very stable U-shell is produced.

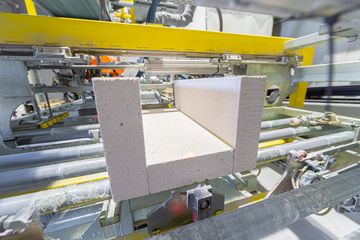

- For the hotmelt process, we have developed our own fully automatic U-shells gluing station. During the production process an AAC block is transferred by a robot from the pallet to the sawing station where it is cut into suitably sized pieces with a powerful saw. The sawn AAC panels are then fed to the gluing station. There they are formed to a robust U-shell using a special hot-melt adhesive. At the end of the production process the robot takes the finished U-shells and stacks them on a pallet.

In addition to this fully automated solution we also offer a U-shells brick bonding station with manual feeding.

For the purposes of perforated blocks production, our powerful perforation-drilling machine is used. First, a robot brings the solid blocks to a turning device that rotates the block by 90°. Then it is placed by the robot on the perforation-drilling machine. Here, channels for reinforcing material and various other channels are drilled with high precision. The robot brings the finished perforated block back to the turning device to rotate it again through 90° and then stacks it on the pallet.