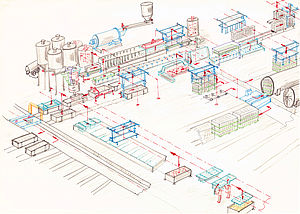

Raw materials processing systems

The production systems in our autoclaved aerated concrete plants are equipped with the latest technology. The main systems used in the area of raw materials processing include:

- Sand feeding with dosing devices

- Ball mills for wet grinding

- Sludge tanks with agitators

- Silos for solids

- Aluminium plants

A variety of raw materials can be used for AAC production. It is usually finely ground, silicate-rich quartz sand, quicklime, cement and anhydrite or gypsum (as binders), as well as aluminium paste or powder (as foaming agent) and water. Fly ash is a popular alternative to sand.

In special tests, the suitability of raw materials is tested and confirmed prior to their use. Do you not want to arrange these tests yourselves? We would be happy to carry out tests for you as a part of our broad service.

How does the raw materials processing work in the plants? A predetermined quantity of water as well as precisely dosed quartz sand are fed to the ball mill for wet grinding. Here both components are mixed to form the sandy sludge. Using the latest technology available, the desired sand sludge density and the grinding fineness are precisely set. The capacity of the mill depends on the level of the total production and the product range to be manufactured (for example block density, or the use of reinforcing elements).

At the end of the grinding process the sand sludge is temporarily stored in large tanks. Our special tank agitators maintain the homogeneous nature of the sludge and prevent any sedimentation.

In the storage silos, the solids (quicklime, cement and anhydrite (gypsum)) are intermittently stored. The silos are equipped with discharge devices that ensure an even and controlled emptying of the silo.

In the aluminium plant, the aluminium paste is dosed either batch-wise or daily quantity-wise before it is mixed with water and fed to the mixer.

All the system components used are equipped with filling level monitors.